<<<<Mirror box & Electronics

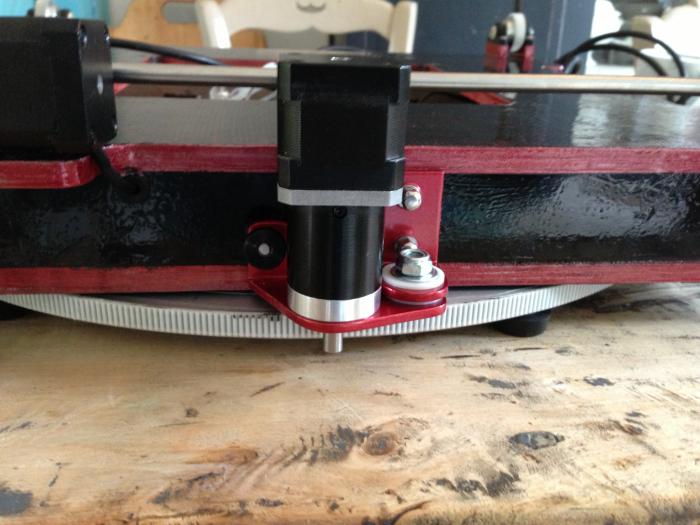

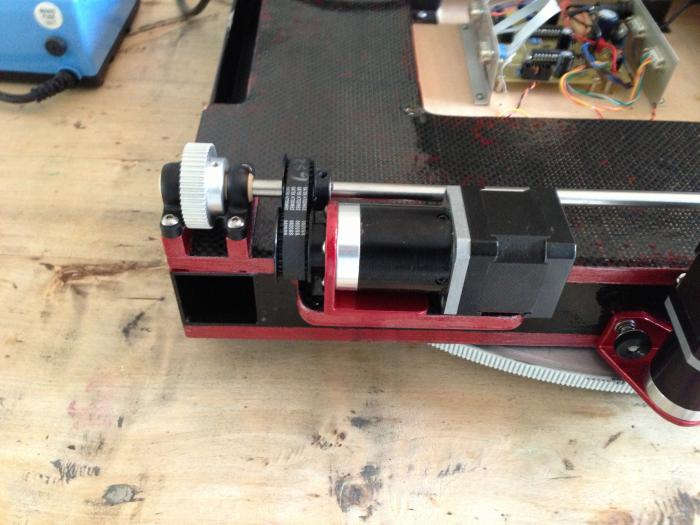

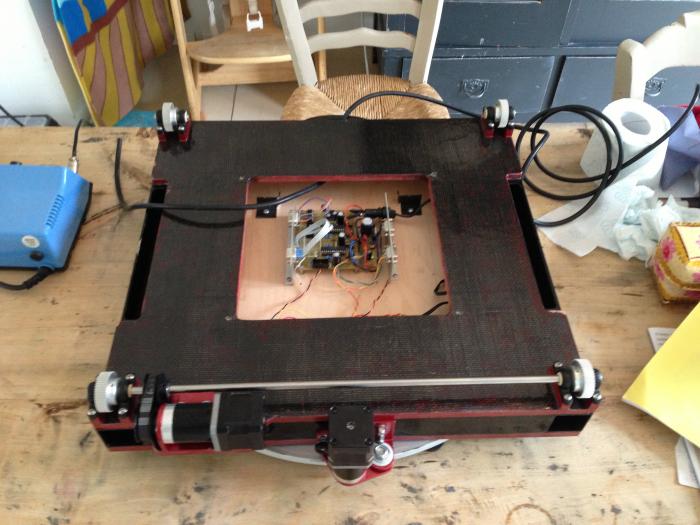

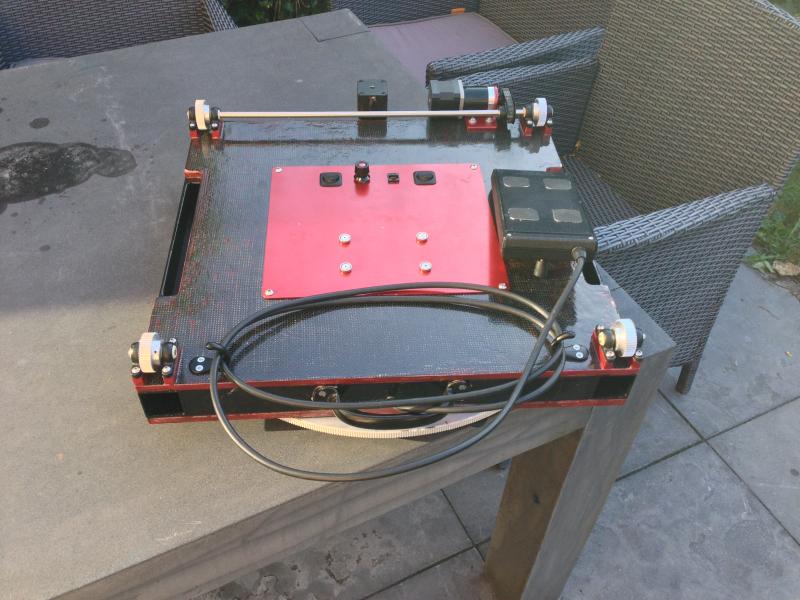

Azimuth platform

This part needed to house the Goto computer, both stepper motors for drive and the main 12 volt powersource. It also needed to be strong, carrying around 50 kg. I sandwiched four beams of 40×40 mm aluminium between 12 mm of plywood and laminated the wood with carbon. As a azimuth bearing a used a lazy suzan table bearing. The 4 cm clearing was just enough to house two 12 volt lithium batteries and the Goto computer. The altitude bearings are driven on both sides for additional stability.

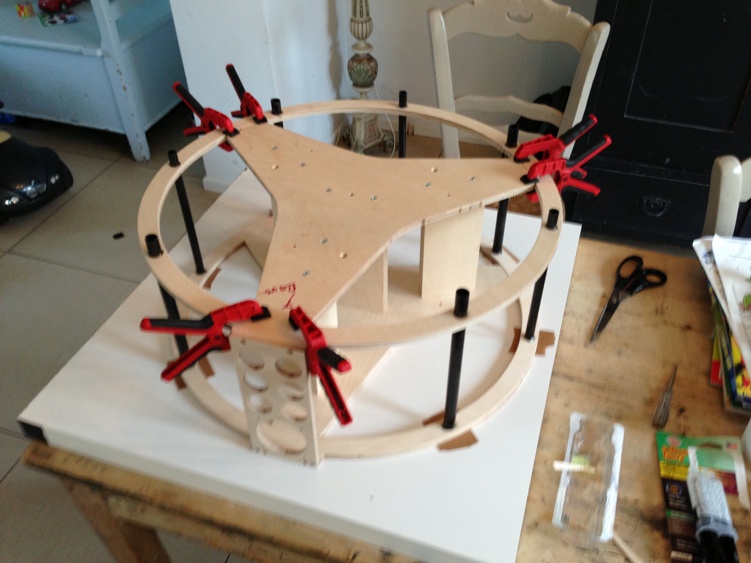

Secondary ring

The secondary ring needed to be as light as possible, but stiff enough for a 110 mm secondary mirror and the additional weight of the tertiary holders and their mirrors. I uses 9 mm wood for the rotating top rings. The base for the rings is a sandwich construction with 3 mm plywood wood and PU foam. The supporting struts are carbon rods

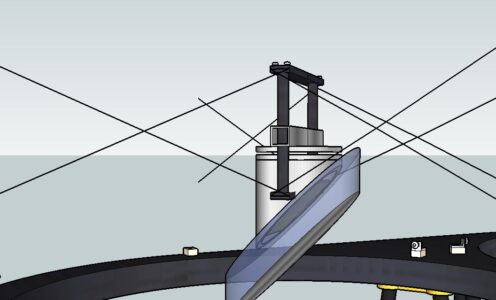

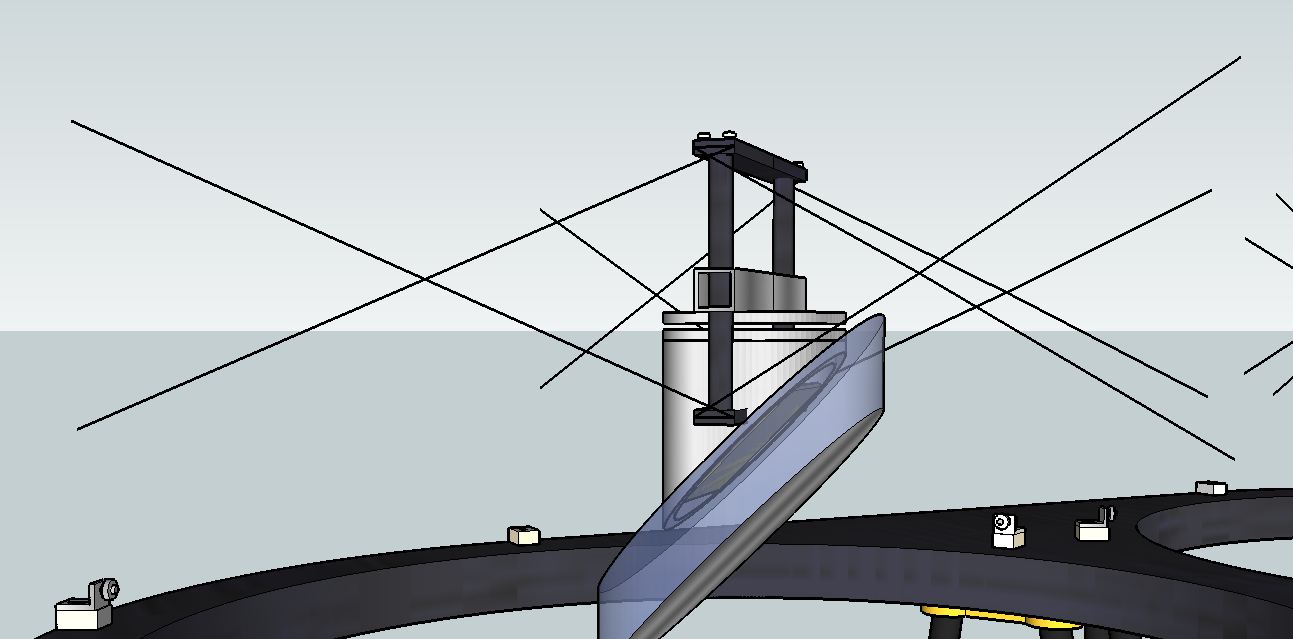

Secondary Mirror Holder

I spent a lot of time designing different secondary holders to try and keep the top rings as compact as possible. This was paramount since I had placed the rings very close together (which made it possible to limit the size of the secondary mirror). The rings had to be lower than than eyepiece high level or they would be touching the observers head. In the end I went with a string concept. Key to getting a things compact is where you attach the strings to the holder. I put a lot of thought into lowering the positions on the holder for the attached strings a far as possible.

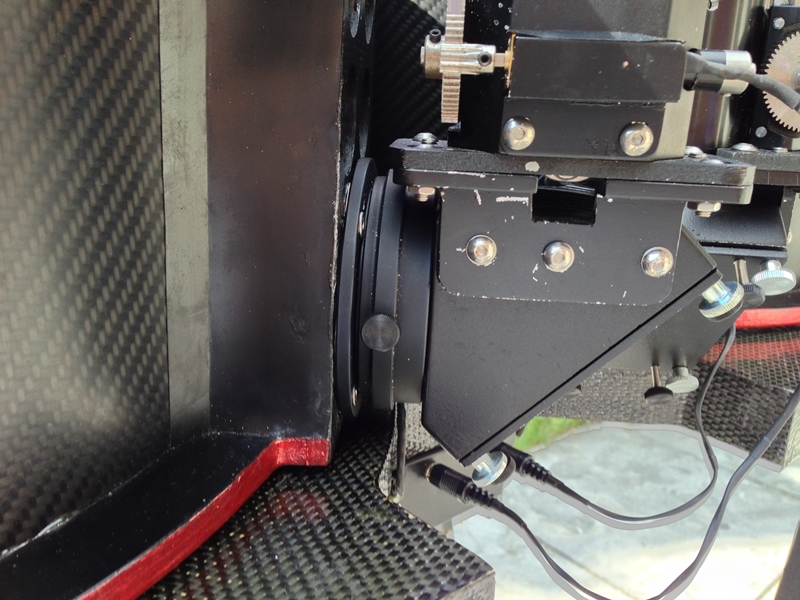

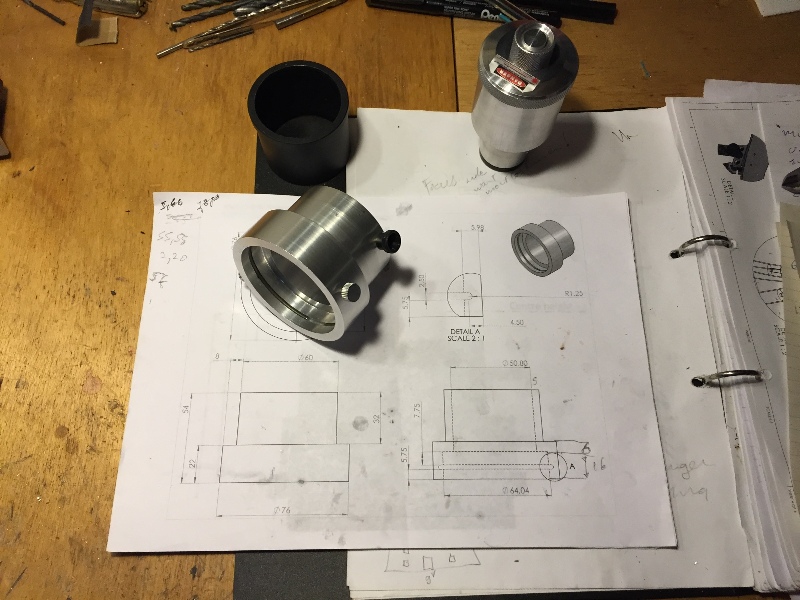

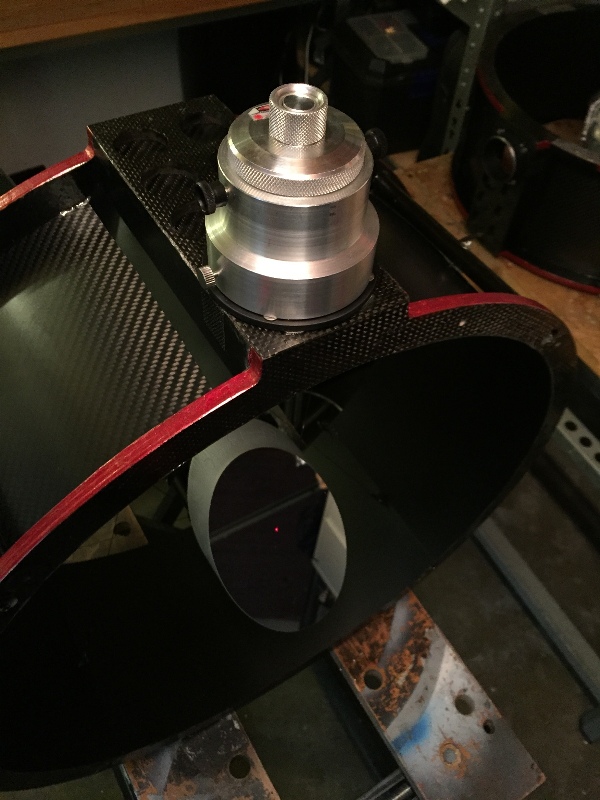

Tertairy Holder & Focuser

For the tertiary holders I used two diagonals that were cut at an angle of 45 degrees. This setup is a copy of the design Arie Otten uses for his binoscopes. Arie is an experienced telescope maker from the Netherlands and has successfully build a lot of binoscopes. The focusers are JMI 2 inch Reverse Crayford Focusers. The tertiary assemblies are attached to the rings with custom made couplings. I also made a special coupling for the lasercollimator with a small lathe.